There are various types of Japanese steel, from stainless steel to carbon steel, which are used for knife, building construction, car manufacturing… etc. And high quality steels are mainly used for knives.

Since the time of the Samurai, Japanese people are particular about swords, and have evolved their quality. And now, we can see various types of Japanese steel through kitchen knives.

On this page are explained the characteristics of each steel and also presented some recommended knives. Hopefully it will help you better understand Japanese steel.

Definition of steel

Steel is what added carbon to iron.

Iron + carbon = steel

Steel and iron are classified by carbon content.

- Iron: containing 0 – 0.04% of carbon

- Steel: containing 0.04 – 2% of carbon

And Japanese steel can be divided into two types: carbon steel and stainless steel.

- Carbon steel – It has a higher carbon content than stainless steel and harder than stainless steel. It’s easy to rust.

- Stainless Steel – Contains a lot of chrome and it has resistance to oxidation.

Types of Japanese carbon steel

| Name of steel | HRC (hardness) | carbon% | Chrom |

| Aogami super | Around 65 | 1.45 | |

| Aogami #1 | Around 64 | 1.3 | |

| Aogami #2 | Around 63 | 1.2 | |

| Sihrogami #1 | Around 63 | 1.2 | |

| Sihrogami #2 | Around 62 | 1.1 |

- The higher the carbon content, the higher the hardness (HRC). And harder it is, the sharper it becomes. Hard steel is suitable for knives, so they are used as materials for Japanese knives.

- Carbon steel knives are very sharp, but they have the disadvantage of being easily rusted.

Aogami(Blue) super steel

Aogami super is the highest quality carbon steel in Japan. It has extremely high hardness and is used for the high class Santoku and Gyuto knives. Depending on the manufacturing process, but most Aogami super knife can be said to be sharp.

(Aogami super santoku)

(Aogami super gyuto)

Aogami(Blue) #1 steel

By adding a little bit of chromium and tungsten to Shirogami 1 (white #1 steel), the difficulty of heat treatment has been solved, and stickiness (hard to chip) and abrasion resistance (long lasting sharpness) have been improved. It is used for Santoku and Chef’s knives, and occasionally for Japanese traditional knives such as Deba and Yanagiba, but it is not a general steel.

(Aogami#1 steel Japanese usuba)

Aogami(Blue) #2 steel

By adding a little bit of chromium and tungsten to Shirogami 2 (white #2 steel), the difficulty of heat treatment has been solved, and improved stickiness (difficult to chip) and abrasion resistance (long lasting sharp ). Many craftsmen who make hand forged knives prefer Aogami #2 steel, and it is used for various knives such as Santoku, Gyuto, Deba, and Yanagiba.

(Aogami#2 steel gyuto)

(Aogami#2 Damascus steel gyuto)

Shirogami(White) #1 steel

It is a steel with more carbon content than Shirogami2 (white #2 steel), and improved hardness and sharpness. Some craftsmen say that Shirogami#1 is the best steel. But high skills are required to handle this steel properly, and currently there are few craftsmen with such skills, that is why Shirogami#1 knives are rare.

(Shirogami#1 steel santoku)

(Shirogami#1 steel Nakiri)

Shirogami(White) #2 steel

It is a typical steel used for traditional Japanese knives. It is a little difficult to handle but if handled by a skilled blacksmith, it will be possible to obtain a good blade that has hardness, stickiness (hard to chip), long-lasting sharpness. Another advantage of this steel is that it is easy to sharpen.

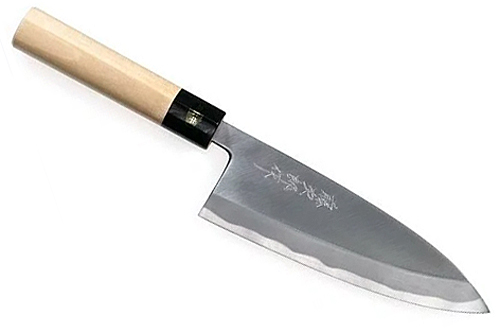

(Shirogami#2 steel deba)

Tamahagane (Tama steel)

It is the steel for Japanese swords. Not used for the kitchen knife. The highest quality Tamahagane has a carbon content of approximately 1.5% and does not contain impurities, so it is called as the purest steel in the world. There are some kitchen knives named Tamahagane, but in reality this steel is not used.

(We are not sure that material of these Japanese swords is Tamahagane)

Types of Japanese stainless steel

| Name of steel | HRC (hardness) | Carbon% | Chrom% |

| Gingami #3 | Around 61 | 1.0 | 13 |

| VG10 | Around 61 | 1.0 | 15 |

| AUS10 | Around 61 | 0.95-1.1 | 13 |

| Powdered SPG2 | Around 62 | 1.4 | 15 |

| Powdered R2 | Around 62 | 1.4 | 15 |

| Molybden | Around 58 | no data | no data |

| 440-A | Around 54 | 0.6-0.75 | 17 |

- These steels are used as materials for knives.

- Stainless steel has a high chrome content and is less likely to rust. (Steel that contains 11% or more chrome is called stainless steel.)

Gingami#3 steel

Gingami#3 is a steel with more than 13% chromium added to Shirogami carbon steel. Although Gingami#3 is stainless steel, it has characteristic and sharpness close to carbon steel. Because this is the steel of Hitachi Metal which manufactures all carbon steel in Japan. If you want a carbon steel knife but don’t want rust, Gingami#3 steel knife is recommend.

(Gingami#3 deba)

(Gingami#3 gyuto)

VG10 steel

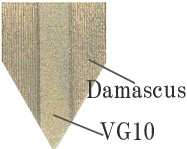

VG10 steel contains high concentrations of carbon, chromium and cobalt. This means that it is hard (sharp), has abrasion resistance (long lasting sharpness), sticky (hard to chip) and does not rust easily. VG10 is a well-balanced steel and is often used as a material for cutting edges of Damascus knives.

(VG10 Damascus kiritsuke gyuto)

(VG10 Damascus santoku)

Powdered SPG2 steel

It is high-grade stainless steel with a large amount of components such as carbon, chromium, tungsten, molybdenum and vanadium. It is hard and has strong rust resistance. However, it is a little difficult to sharpen with a whetstone. Even with the same hardness, stainless steel is more difficult to sharpen than carbon steel.

(Powdered SPG2 steel Japanese sujihiki)

(Powdered SPG2 steel santoku)

Powdered R2

Powdered high speed steel from Kobe steel Ltd. A large amount of carbon, chromium, tungsten, molybdenum and vanadium… etc are added to steel and it is hard and has strong rust resistance. However, it is a little difficult to sharpen with a whetstone. Even with the same hardness, stainless steel is more difficult to sharpen than carbon steel.

(Powdered R2 steel gyuto)

Molybdenum

Molybdenum is not an official name, but common steel containing molybdenum and vanadium is called molybdenum steel. Molybdenum and vanadium have the effect of increasing strength (sharpness and abrasion resistance) and sticky (hard to chip). It is mainly used as a material for medical scalpels and home use kitchen knives.

(Molybdenum steel Japanese gyuto)

440-A steel

Aichi Steel Ltd.’s stainless steel containing 17% chromium. Generally not used for the kitchen knife, as it is not very hard (not very sharp), but it is used for diving knives, because it is very resistant to rust.

Damascus steel

Damascus steel is what is obtained by layering several different steel materials. There are various types, such as 17 layers, 33 layers, 65 layers, etc. The more layers it becomes more beautiful , but it has nothing to do with the sharpness or quality of the knife. There are many benefits to laminating steel, but 17 layers are sufficient. Sharpness is determined by the quality of the steel used in the center.

Additional explanation

The quality of steel products such as knives is not determined solely by the type of steel. With the correct heat treatment(hardening and tempering), the steel can be in the best condition.